Exhibits

Innovation on manufacturing of chemicals with sequential and continuous-flow synthesis

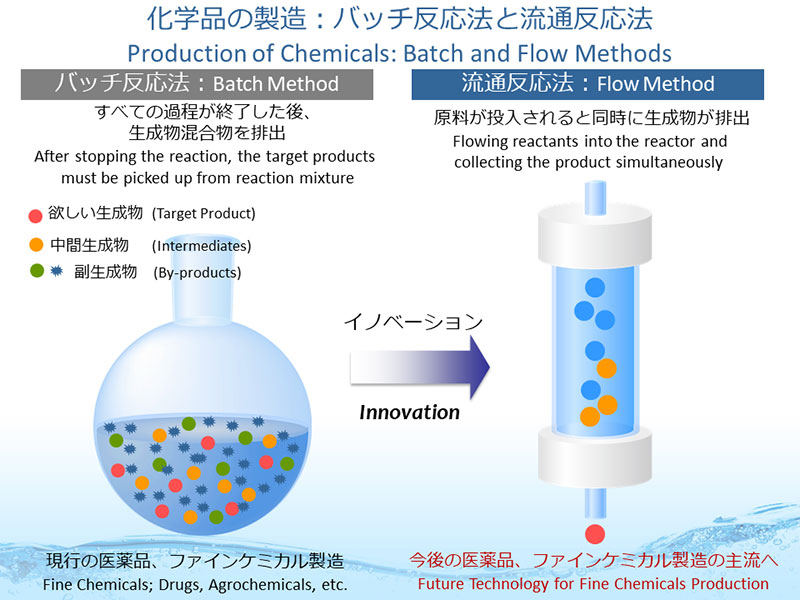

Production of Chemicals: Batch and Flow Methods

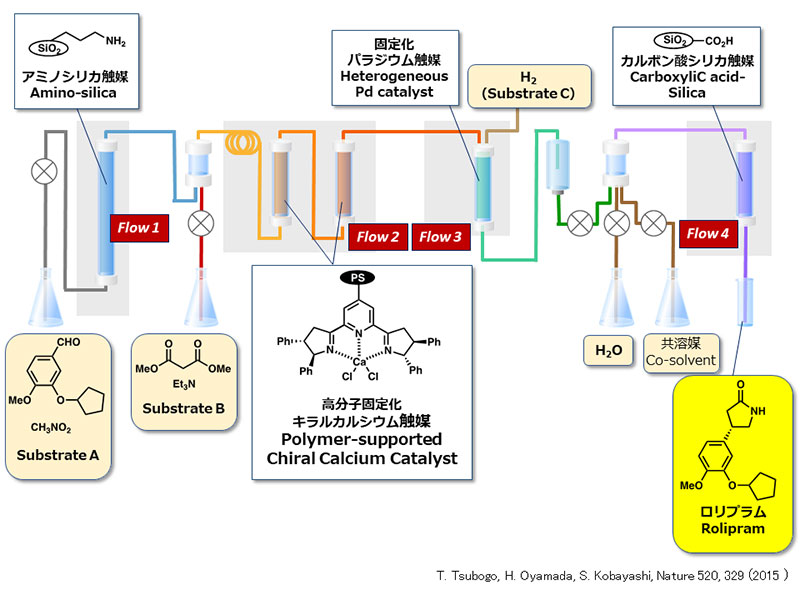

Sequential Continuous-flow Synthesis of a Drug Molecule, (S)-Rolipram

Most research in synthetic organic chemistry has long been conducted using batch methods. This approach is currently by far the most used synthetic method in almost all laboratories in academia and the fine-chemical industry. Nonetheless, for several other industrial products, continuous manufacturing is an important technique. For the establishment of continuous manufacturing in the chemical industry, continuous-flow systems operated at steady state are essential to realize the on-demand production of chemicals. In general, however, synthesis by flow methods seems to be more difficult than by batch methods. Synthesis by flow methods may be applicable to chemical products through simple processes, but it is difficult to apply to the synthesis of more complicated molecules. In 2015, researchers from the Synthetic Organic Chemistry Laboratory, led by Professor Shu Kobayashi in the School of Science’s Department of Chemistry, The University of Tokyo, had shown the continuous-flow synthesis of a drug molecule using only packed-bed column reactors with heterogeneous catalysts. Their results demonstrate one-flow production of chemical substances through multistep chemical transformations using only heterogeneous catalysts, without the isolation of any intermediates and without the separation of any catalysts, co-products, by-products, and excess reagents. They anticipate that such syntheses will open the door to a green and sustainable future in the chemical industry.

Responsibility for wording of the article

Shu Kobayashi, Professor, Chemistry [2022]